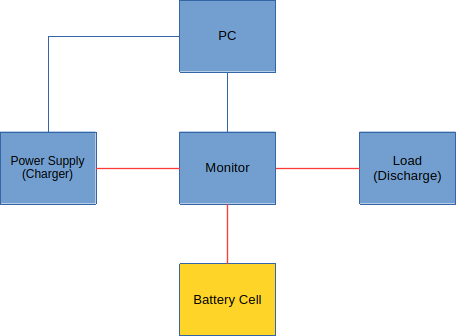

The principal setup for the project is as follows:

The PC is used to record & control the experiments.

The Charger is used to charge the battery.

The Monitor is a box that records the charging process as well as the discharging process.

The Load is used to discharge the battery.

And finally the yellow box is the cell under testing.

The requirements for the components are (roughly) as follows:

Power Supply/Charger: If possible (budget!) it should be controllable from the PC. I.e. the PC should be able to set current and voltage maximums for a charge cycle. This could also be done manually as a work around if costs are prohibitive. It should be able to limit currents using increments of 10mA and voltages using increments of 100mV. An emergency switch-off input is preferable. Minimum voltage setting should be lower or equal to 1V. Maximum power should at least 1A.

Monitor: Should be able to record voltages and current during charge and discharge cycles. The resolution should be better than 10mA and 10mV respectively. These measurements must be transmitted to the PC, or stored in internal memory for later transfer to the PC. Recording cell temperatures is desirable.

Load: Preferably the load should be under control of the PC as well. But especially in the beginning a simple solution would be to use a power resistor mounted on a heat sink. Since only a single cell provides the power to be dissipated, this is not expected to exceed 1W in the initial phases of the project.

PC: A Linux OS would be preferred, but the SW available for the charger and/or monitor will decide on which platform the PC will be run. Another option might be to use a controller like the Arduino, STM32 or Raspberry, but in that case the project would expand to include development of the test software. Possible, but it would cause delays in the project.

At this point in time no component selection has been made. Hence it is possible that the project setup may change a little. Nevertheless, it is quite likely that the setup will resemble the above setup.