Nacelle design completed (more or less)

This week I finished the nacelle. The main body is complete, but some smal bits (fences, cooler adapters) still have to be added.

Total weight so far, as reported by Fusion360 is about 85 grams. Which I think is acceptable.

I decided against using CFRP for the cowling because of weight. From doing some testing with the design for the floats, CFRP is about 10 times as heavy as balsa wood. But savings in the form of thickness are just about 5 times. Hence the weight of a part in CFRP as opposed to balsa is still twice as heavy.

Where structural issues are important it makes sense to use CFRP, but I see no such issues with the nacelles, and hence will do them in balsa entirely. (Well, including some bits of other wood types where needed)

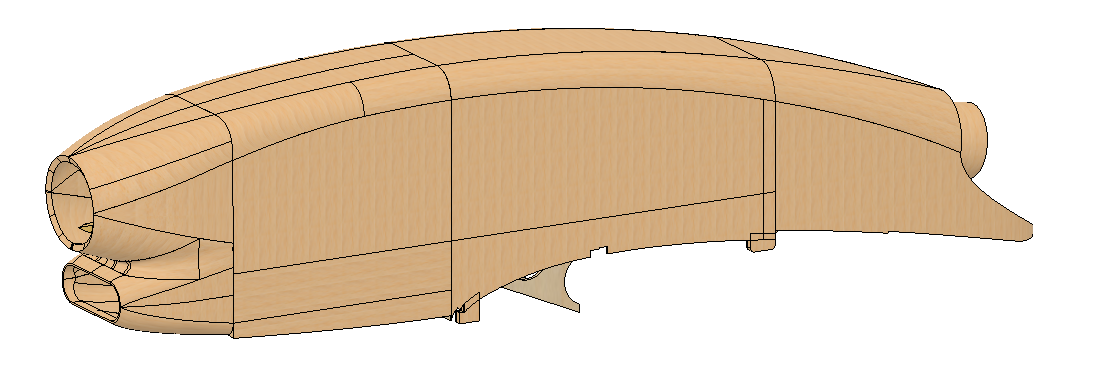

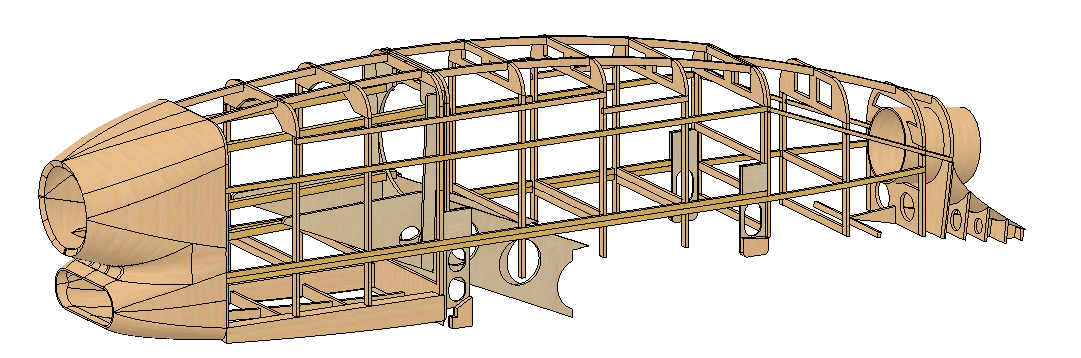

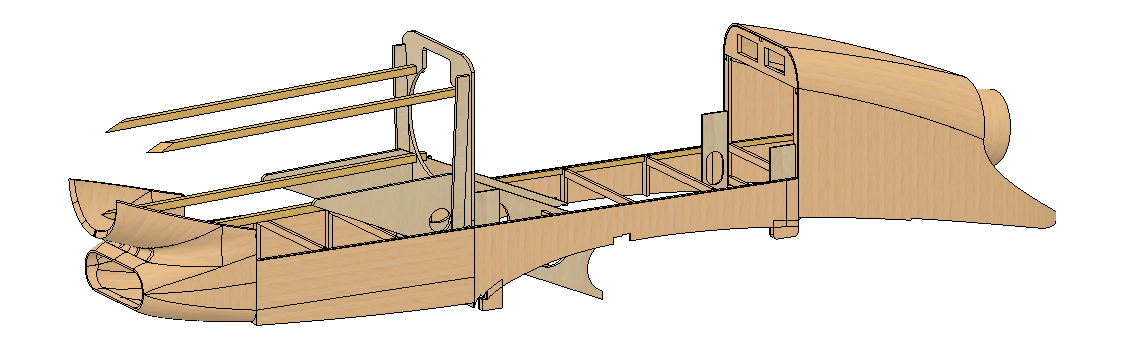

The pictures:

As you can see, the air inlet and propeller adapter will be CNC-ed out of solid balasa. The entire nacelle is hollow thus air can flow through for the cooling of the engine.

The engine bay is visible when removing the cowling. An axis extender will probably be necessary for most engines. Also, the engine bay is not complete, some addition struts or other structural improvements will be added when the engine has been selected.

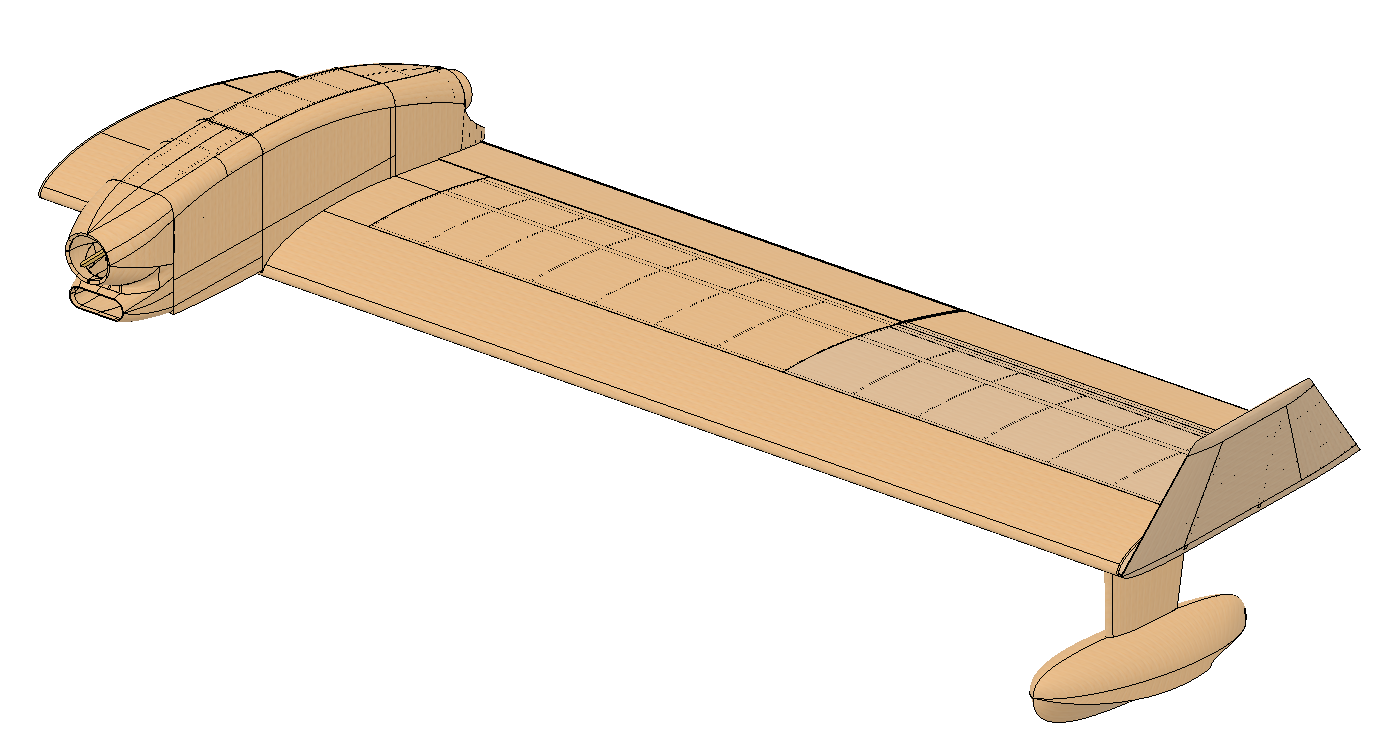

The whole wing, but without the nacelle adapter, fences and cooler.